PAL1000 method for gold assay

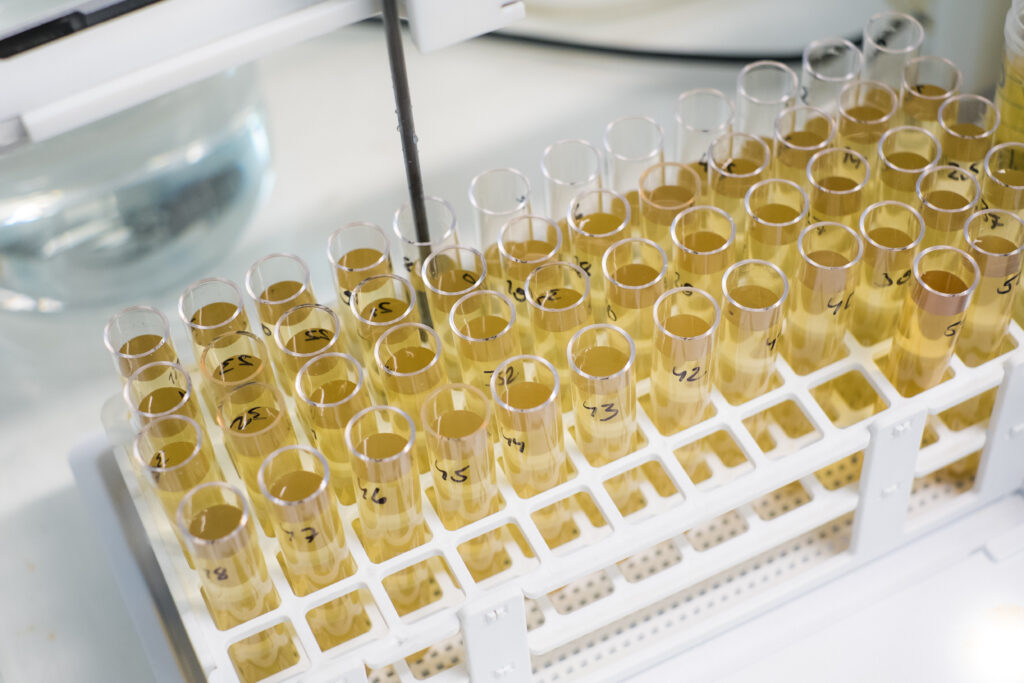

In PAL1000 method, ore samples are simultaneously pulverised and dissolved in a cyanide solution to determine their gold content. The concentration of gold is measured using an AAS analyser (Atomic Absorption Spectrometer) which measures the gold content directly from the dissolved sample or from the organic phase after liquid-liquid extraction.

This method enables the complete analysis of samples as large as one kilogram, which leads to an extremely high representativeness of the analysis result – a significant advantage especially in gold assays. PAL1000 method is included in our scope of accreditation (T342 accredited by FINAS Finnish Accreditation Service, accreditation requirement SFS-EN ISO/IEC 17025).

Contact us for further information on the PAL1000 method

Key advantages of the PAL1000-method

Representative

• Analysis of samples of up to 1000 g, minimising the Gold Nugget Effect

• The simultaneous performance of pulverising and dissolution eliminates the mechanical smearing of the gold nuggets onto the walls of the pulveriser container (and the wastage it causes in the analysis of coarse gold) which often occurs in traditional pulverising

Fast

• Customisable express delivery in just 1–2 days, typical delivery time 1–2 weeks

• Analysis performed at our laboratory in Kempele

• Pick-up service for sample pallets available

High quality

• We perform a quality check for each PAL1000 leach batch using certified reference materials, blank samples and parallel analyses.

• Prior to the actual analysis, we recommend that the test samples in the ore body in question should be subjected to a residual gold assay after the cyanide extraction. Most of our clients in the Nordic countries achieve a cyanide leach recovery of 95–100 %.

• PAL1000 method is included in our scope of accreditation (T342 accredited by FINAS Finnish Accreditation Service, accreditation requirement SFS-EN ISO/IEC 17025).

Cost-effective

• The sample doesn’t need to be pulverised beforehand, only crushed to a particle size of < 2 mm

• Efficient analysis – the machine can process 52 samples at a time

• The total cost is typically lower than in the Fire assay method

Taking care of the environment is one of our foremost values

We have developed a waste purifying process specifically for the waste generated in the PAL1000 process: solid particles are separated from liquid, cyanide and other harmful substances are eliminated using different chemical reactions, flocculation and ion exchange. The aim of the process is to make the resulting wastewater non-toxic and safe for sewage disposal.

We can customise the PAL1000 service package to meet the needs of our clients. We take pride of our punctual delivery times, which can be agreed upon in advance. It is also possible to adjust the sample amount of the PAL1000 method within a range of 100–1000 grams and lower the determination limit through an organic liquid-liquid extraction.